Cold Rolled Bar rod manufacturing company in India

Cold Rolled Bar rod manufacturer Cold Rolled Bar rod suppliers Cold Rolled Bar rod stockists Cold Rolled Bar rod exporter Bhopal, Madhya Pradesh

Cold Rolled Bar UAE | Cold Rolled Bar Indonesia | Cold Rolled Bar Australia | Cold Rolled Bar Malaysia | Cold Rolled Bar Singapore | Cold Rolled Bar Iran | Brazil Cold Rolled Bar

Contents

- What is Cold Rolled Bar?

- Cold Rolled Bar specification

- Cold Rolled Bar price list

- Cold Rolled Bar leading manufacturers

- Cold Rolled Bar buyers

- What & where supplied?

- Cold Rolled Bar related products & stock

- Why Us?

- Cold rolled / cold drawn steel Bar Process chart

- Why use Cold Rolled Bar?

Established in 2006, MD Exports LLP is a pioneer of the nation’s steel industry and a leading manufacturer of long products ranging from bars, rods. As a result of our international network, we are helping our steel bar & rods customers to export their products such as Stainless Steel, Carbon Steel, Alloy Steel, Duplex Stainless Steel, Super Duplex, Copper Nickel, Hastelloy, Inconel, Monel, Titanium, 253MA, 254SMO, AL6XN, Custom 450, Jethete M152, Beryllium Copper Bar Rod etc. These products are exported to countries such as Singapore, Indonesia, Brunei, Myanmar, Hong Kong, Australia, Fiji, New Zealand, Papua New Guinea, Mauritius, Maldives, Sri Lanka, Pakistan, South Africa, Madagascar, Egypt, UAE, Amman, Kuwait, Bahrain, United Kingdom, Denmark, Switzerland and Germany. We are staffed by a team of well-trained technical personnel, providing technical support and services relating to quality and applications of our products. Our technical team is able to advise on the most appropriate product quality to meet your requirements.

Cold Rolled Bar

Cold Rolled“Cold Roll” is the nickname for steel that is produced in the “cold rolling” method, processed at close to normal room temperatures. Cold Roll is limited to a few shapes but comes in many finishes and offers superior strength and machinability. We are specialized to manufacture cold rolled bar in Stainless Steel grades such as 303 Stainless Steel, 304 Stainless Steel, 304L Stainless Steel, 304H Stainless Steel, 316 Stainless Steel, 316L Stainless Steel, 316H Stainless Steel, 316Ti Stainless Steel, 321 Stainless Steel, 321H Stainless Steel, 329 Stainless Steel, 347 Stainless Steel, 347H Stainless Steel, 310 Stainless Steel, 310S Stainless Steel etc. We also produce 317/317L Stainless Steel also known as UNS S31700, 317/317L Dual Certified include increased strength, corrosion resistance (including crevice and pitting), higher tensile strength and a higher stress-to-rupture ratio. Cold rolled steel is essentially hot rolled steel that has had further processing. The steel is processed further in cold reduction mills, where the material is cooled (at room temperature) followed by annealing and/or tempers rolling. This process will produce steel with closer dimensional tolerances and a wider range of surface finishes. The term Cold Rolled is mistakenly used on all products, when actually the product name refers to the rolling of flat rolled sheet and coil products. When referring to bar products, the term used is “cold finishing”, which usually consists of cold drawing and/or turning, grinding and polishing. This process results in higher yield points and has four main advantages:

All cold products provide a superior surface finish, and are superior in tolerance, concentricity, and straightness when compared to hot rolled. Cold finished bars are typically harder to work with than hot rolled due to the increased carbon content. However, this cannot be said about cold rolled sheet and hot rolled sheet. With these two products, the cold rolled product has low carbon content and it is typically annealed, making it softer than hot rolled sheet. Cold rolling occurs with the metal below its recrystallization temperature (usually at room temperature), which increases the strength via strain hardening up to 20%. It also improves the surface finish and holds tighter tolerances. Commonly cold-rolled products include sheets, strips, bars, and rods; these products are usually smaller than the same products that are hot rolled. Because of the smaller size of the workpieces and their greater strength, as compared to hot rolled stock, four-high or cluster mills are used. Cold rolling cannot reduce the thickness of a workpiece as much as hot rolling in a single pass. Cold Rolled Bar Cold Rolled Hex Bar Cold Rolled flat Bar Cold Rolled bright Bar Cold Rolled Bars Cold Rolled rod Cold Rolled round Bar

|

Cold Rolled Bar specification

Cold Rolled Bar

Cold rolled stainless steel Bar Cold rolled stainless steel Bar

|

Cold rolled Carbon Steel Bar Cold rolled Carbon Steel Bar

|

Cold rolled Alloy Steel Bar Cold rolled Alloy Steel Bar

|

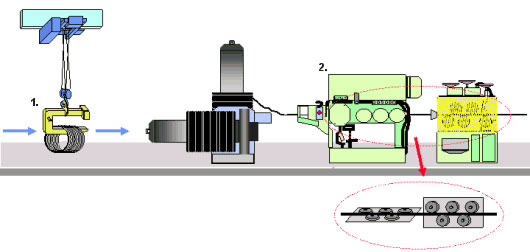

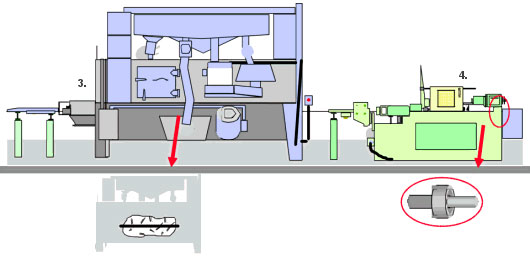

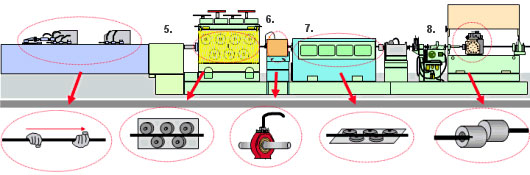

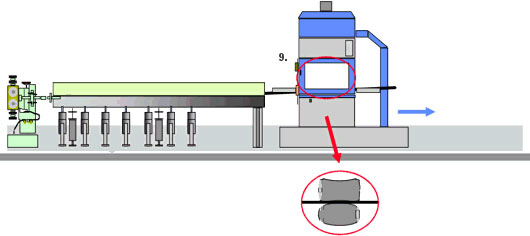

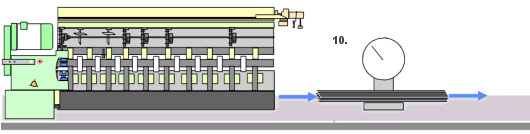

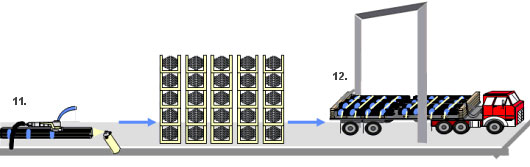

Cold rolled / cold drawn steel Bar Process chart

1. Our process begins with either hot-rolled steel coils or hot-rolled straight bars from the mill. When hot-rolled bars are used, they are drawn individually. When coils are used, overhead cranes use C-hooks to safely lift the coil onto the “Payoff-Decoiler.”

2. Steel unwraps from the “Payoff De-Coiler” and is fed through the horizontal and vertical pre-straightener rollers to “break the memory” of the coil.

3. Steel continues on through the shot blaster so that the surface of the bar can be cleaned of all scale and rust.

4. Now the steel is push-pointed through a die. The drawing unit will then pull the steel through that same die, in a continuous motion.

5. Continuous straightening is maintained by passing the steel through more rollers.

6. Non-destructive testing is in place on all drive lines to ensure that surface defects from the raw materials are being detected and sorted out.

7. More straightening processes are in place throughout the draw line.

8. Shear barrels or shear knives will shear or cut the bar to the customer’s desired length.

9. The final straightening process occurs at the 2-roll straightener when the bar passes through the large concave and convex rolls. Guide blades, angles and pressure all contribute to the final straightness of the bar.

10. Cold finished straight bars accumulate at the delivery table where they are weighed.

11. The finished bundle is banded with steel strapping and steel banding clips. The bundle is painted on the end per the customer spec and identified with a tag.

12. Customers notify us when they need their steel, and the bundles are selected from the inventory stock and loaded on flat bed trucks for shipment.

MD Exports LLP offers following processing for Cold Rolled Bar

Cold Rolled Bar price list

- aisi 314 stainless steel bar/303se stainless steel round bar

US $1000-5000 / Ton (FOB Price) - astm a276 410 stainless steel round bar

US $1.5-15 / Kilogram (FOB Price) - SUS 301 303 304,310 ,416 ,441,446 stainless steel round bar Made in China

US $1500-7000 / Metric Ton (FOB Price) - 400 series 420 Stainless Steel Round Bar

US $1500-2300 / Metric Ton (FOB Price) - sus 430 round bar/stainless steel round bars 3mm

US $1000-5000 / Metric Ton (FOB Price) - 430f stainless steel round bar

US $1200-7000 / Metric Ton (FOB Price) - aisi 431 stainless steel round bar

US $1.5-15 / Kilogram (FOB Price) - stainless steel round bar 440c

US $1000-5000 / Ton (FOB Price) - AISI 446 Stainless Steel Round Bar

US $1200-1700 / Metric Ton (FOB Price) - Stainless Steel Round Bar AISI 422

US $900-5000 / Metric Ton (FOB Price) - 904L stainless steel round bar cold rolled

US $1500-3000 / Ton (FOB Price) - Stainless Steel 17-4ph Round Bar

US $1500-2000 / Metric Ton (FOB Price) - 15-5ph stainless steel round bar factory

US $1500-7000 / Metric Ton (FOB Price) - Stainless Steel Round Stainless 13-8MO / 13-8PH / UNS S13800

US $1500-7000 / Metric Ton (FOB Price) - Alloy 660 Round Bar

US $10-20 / Kilogram (FOB Price) - Nitronic 50 /22Cr-13Ni-5Mn stainless steel round bar

US $2000-3000 / Ton (FOB Price) - Competitive price stainless steel nitronic 60 round bar black bright manufacturer

US $5000-8000 / Ton (FOB Price)

» Click here to view grade wise Price list for Cold Rolled Bar

Cold Rolled Bar leading manufacturers

Our manufacturing from base raw material of Wire Rod, Round Bar of VSP (RINL), SAIL, Thyssenkrupp, Outokumpu, MUKAND, USHA MARTIN , PANCHMAHAL, RIMZIM, JAYASWAL NECO, BHUSHAN STEEL, MITTAL, JSW, IMPORTED.

|

Thyssenkrupp / Thyssenkrupp Round bar |

Outokumpu / Outokumpu Round bar |

Mukand / Mukand steel bar |

Cold Rolled Bar buyers

Cold Rolled Bar can be used for a number of different applications, including:

- Screw machine products

- Shafts

- Valves

- Fittings

- Gears

- Fasteners

- Food processing equipment

- Instruments

- Screws

- Bearings

- Mining machinery

- Aircraft parts, exhaust manifolds

- Pumps

What & where supplied?

| Cold Rolled Bar Rod Suppliers from South Africa Cold Rolled Bar Rod United Arab Emirates Cold Rolled Bar Rod Traders Calgary Canada Cold Rolled Bar Rod Exporters Dubai Cold Rolled Bar Rod United Arab Emirates Cold Rolled Bar Rod Suppliers Bhopal, Madhya Pradesh Cold Rolled Bar Rod Exporters India Cold Rolled Bar Rod Stockist Dallas Cold Rolled Bar Rod Importers USA Cold Rolled Bar Rod Importers Seattle Cold Rolled Bar Rod Suppliers Singapore Cold Rolled Bar Rod Suppliers from Malaysia Cold Rolled Bar Rod Stockist New Zealand Cold Rolled Bar Rod Traders United States Cold Rolled Bar Rod Suppliers Canada Cold Rolled Bar Rod Suppliers Indonesia Cold Rolled Bar Rod Exporters South Korea Cold Rolled Bar Rod Stockist Iran Cold Rolled Bar Rod Suppliers Norway Cold Rolled Bar Rod Chennai Cold Rolled Bar Rod Suppliers Pune Cold Rolled Bar Rod Suppliers New Delhi Cold Rolled Bar Rod Suppliers from Netherlands Cold Rolled Bar Rod Manufacturers Denmark Cold Rolled Bar Rod Importers Jakarta, Indonesia Cold Rolled Bar Rod Houston, TX Cold Rolled Bar Rod Philadelphia, PA Cold Rolled Bar Rod Manufacturers Durban Cold Rolled Bar Rod Traders Johannesburg Cold Rolled Bar Rod Stockist Pretoria Cold Rolled Bar Rod Importers Soweto Cold Rolled Bar Rod Port Elizabeth Cold Rolled Bar Rod Exporters Benoni Cold Rolled Bar Rod Suppliers Vereeniging Cold Rolled Bar Rod Suppliers Bloemfontein Cold Rolled Bar Rod Suppliers from Newcastle Cold Rolled Bar Rod Stockist East London Cold Rolled Bar Rod Manufacturers Welkom |

Cold Rolled Bar Rod King Williams Town Cold Rolled Bar Rod Manufacturers Nigel Cold Rolled Bar Rod Traders Pietersburg Cold Rolled Bar Rod Suppliers Abu Dhabi Cold Rolled Bar Rod Suppliers Nelspruit Cold Rolled Bar Rod Exporters Qatar Cold Rolled Bar Rod Importers Oman Cold Rolled Bar Rod Potchefstroom Cold Rolled Bar Rod Saudi Arabia Cold Rolled Bar Rod Suppliers from Ajman Cold Rolled Bar Rod Umm al-Quwain Cold Rolled Bar Rod Suppliers Calcutta Cold Rolled Bar Rod Suppliers Pakistan Cold Rolled Bar Rod Suppliers Denmark Cold Rolled Bar Rod Exporters Italy Cold Rolled Bar Rod Manufacturers Australia Cold Rolled Bar Rod Stockist Fujairah Cold Rolled Bar Rod Suppliers Japan Cold Rolled Bar Rod Suppliers from Brazil Cold Rolled Bar Rod Suppliers Peru Cold Rolled Bar Rod Canada Cold Rolled Bar Rod Ras al-Khaimah Cold Rolled Bar Rod Traders Sharjah Cold Rolled Bar Rod Manufacturers Sydney Cold Rolled Bar Rod Melbourne Cold Rolled Bar Rod Stockist Perth Cold Rolled Bar Rod Manufacturers Adelaide Cold Rolled Bar Rod Exporters Hobart Cold Rolled Bar Rod Traders Canberra Cold Rolled Bar Rod Suppliers from Brisbane Cold Rolled Bar Rod Pietermaritzburg Cold Rolled Bar Rod Exporters Rustenburg Cold Rolled Bar Rod Stockist Witbank Cold Rolled Bar Rod Carltonville Cold Rolled Bar Rod Suppliers Klerksdorp Cold Rolled Bar Rod Importers George Cold Rolled Bar Rod Exporters Botshabelo Cold Rolled Bar Rod Suppliers Kimberley |

Cold Rolled Bar related products & stock

Bar & Rod, we manufacture, at a glance:

Stainless steel manufacturing grade at a glance:

Nickel Alloy Bar & Rod at a glance:

List of Countries where MD Exports LLP supply all size & grade Bright Bars / Rods:

Why Should I Order Cold Rolled Bar From MD Exports LLP?

- MD Exports LLP is ISO certified

- MD Exports LLP offers overnight delivery

- Professional packaging ensures that your product is received in top condition

- Our staff has in-depth product knowledge and extensive cross training. They are motivated to give you quick, accurate information-first call, every call!

- Contact us and get the right answers right away!

Why use Cold Rolled Bar?

- The benefits of controlled rolling include better mechanical properties and energy savings

- High strength; Durable; High load bearing capacity

- The cold rolled process creates a finished product that is more precise dimensionally than a hot rolled product. This is because it is already closer to the finished dimension since it has already gone through the cooling process.

- Cold rolled steel is limited to just a few shapes, such as round, square, flat and variations of those types of shapes.

- Finished products created by the cold rolled steel process include bars, strips, rods and sheets which are usually smaller than the same products available through hot rolled methods

- The smaller products are also much more tolerant than the larger hot rolled versions.